Research Article

Karolina Kot vel Ławecka, Dorota Banaszewska , Barbara Biesiada-Drzazga

Department of Breeding Methods and Poultry Breeding, Siedlce University of Natural Sciences and Humanities, Prusa 14, 08-110 Siedlce, Poland

Abstract. The aim of the study was to determine the effect of selected meat packaging systems on certain quality attributes based on the example of breast muscles of broiler chickens. The research material consisted of 120 breast muscles of Ross 308 broiler chickens slaughtered at 36 days of age. The muscles were divided into four groups of 30 each, including one control group. The other three groups were packaged individually in three different packaging variants in accordance with the procedures used at meat processing plants: MAP, on a shrink-wrapped EPS tray and a vacuum. Analyses were performed of the following physical characteristics in the control samples (day 0, before packaging) and experimental samples (after seven days of storage): pH, WHC, EC, drip loss, composition of the mixture in the case of MAP packaging and colour measurement in the CIE L*a*b* system. The meat packed using various systems undergoes some changes during storage. The research confirmed significant differences in the quality characteristics of meat packed by different methods after seven days of storage. Vacuum-packed chicken breast muscles had a lighter colour and the highest electrical conductivity. These muscles also showed a higher drip loss, which may be of importance in processing.

Keywords: meat, quality, packing, broiler chickens

Poultry production is currently the fastest growing segment of the meat industry. The increase in poultry meat production is due to its relatively low production costs, the nutritional, sensory and health properties of poultry meat, and the availability of the raw material [Górska and Wojtysiak 2016Górska, M., Wojtysiak, D. (2016). The white stripping syndrome in the breast meat and meat quality of broiler chickens [Syndrom białych włókien w mięsie piersiowym a jakość mięsa kurcząt brojlerów]. Polskie Drobiarstwo, 9, 38–40 [in Polish].]. This intensive increase in production mainly pertains to meat from broiler chickens, which account for 86% of birds slaughtered for meat globally [Grabowski and Kijowski 2018Grabowski, T., Kijowski, J. (2018). Poultry meat and meat products. Technology, hygiene and quality [Mięso i przetwory drobiowe. Technologia, higiena, jakość]. Wydaw. WNT, Warszawa [in Polish].]. Poland holds a leading position among producers and exporters of this raw material in the European Union [Kozioł and Krzywoń 2014Kozioł, I., Krzywoń, M. (2014). The state of the poultry industry in Poland [Stan przemysłu drobiarskiego w Polsce]. Progress in Economic Sciences, 1, 85–98 [in Polish].]. The share of poultry in the country’s total meat consumption is systematically increasing.

Consumers are paying increasing attention to the quality of the products they purchase, which depends on many attributes (physical, technological, chemical, microbiological, sensory and biochemical) determining their nutritional value [Tougan et al. 2013Tougan, P.U., Dahouda, M., Salifou, C.F., Ahounou, S.G., Kpodekon, M.T., Mensah, G.A, Thewis, A., Karun, I.Y. (2013). Conversion of chicken muscle to meat and factors affecting chicken meat quality: a review. IJAAR, 3, 8, 1–20.]. However, what is most important to consumers is the sensory quality of meat, which includes its texture (hardness and tenderness), juiciness, palatability (smell and taste), and colour [Kołczak 2008Kołczak, T. (2008). Beef quality [Jakość wołowiny]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 56 (1), 5–22 [in Polish].]. Due to the growing demands of consumers and advances in packaging technology, food manufacturers must look for new packaging solutions and modifications of current meat packaging systems in order to ensure the highest possible product quality. Particular attention is also paid to improving the functionality of packaging [Makała 2013Makała, H. (2013). Trends in the meat and meat product packaging market [Trendy na rynku opakowań do mięsa i przetworów]. Gospodarka Mięsna, 8, 34–38 [in Polish].]. Meat quality is determined at all stages of production, from rearing of animals to storage of the meat. Therefore, one of the important factors affecting the quality of poultry meat is the use of an appropriate packaging system.

The type of packaging should be adapted to the properties of the product. Raw meat is included among non-durable goods. Packaging is susceptible to many irreversible physical, chemical and microbiological processes. Currently, the most commonly used packaging systems in the meat industry are modified atmosphere packaging (MAP), controlled atmosphere packaging (CAP), vacuum packaging (VP), and packaging on an EPS tray (with the product covered with shrink wrap), as well as modern packaging systems being introduced to the market, known as intelligent and active packaging. These systems have a positive effect on the quality of the raw material by providing a protective barrier against external factors, extending shelf life, increasing safety, and preserving sensory attributes [Panfil-Kuncewicz et al. 2012Panfil-Kuncewicz, H., Kuncewicz, A., Juśkiewicz, M. (2012). Selected issues in food packaging [Wybrane zagadnienia z opakowalnictwa żywności]. Wydaw. Uniwersytetu Warmińsko-Mazurskiego, Olsztyn, 191–259 [in Polish].]. However, in each of these packaging systems certain changes take place during storage of the product. This is why the right selection of packaging material and technology for poultry meat is so important.

The aim of the study was to determine the effect of selected meat packaging systems on certain quality attributes based on the example of breast muscles of broiler chickens.

The research material consisted of 120 breast muscles of Ross 308 broiler chickens slaughtered at 36 days of age at a poultry meat plant in the Masovian Voivodeship. Immediately after evisceration at the poultry plants (20–30 min after slaughter), individual breast muscles were separated. The muscles were divided into four groups of 30 each, including one control group. The other three groups were packaged individually in three different packaging variants in accordance with the procedures used at meat processing plants:

All muscle groups were transported under refrigeration to the laboratory, where tests were carried out on the control group immediately after transport and on the three groups of packaged muscles after seven days of storage under refrigeration at 2–4°C.

The experiment included of the physical characteristics of the breast muscles in the control samples (day 0, before packaging) and experimental samples (after seven days of storage). Analyses were performed of the following physical characteristics:

The data were analysed using the Statistica package, version 10.0 [StatSoft 2011StatSoft (2011). STATISTICA Version 10.0 PL. Series 1101.]. The significance of differences between groups was determined by the Tukey test.

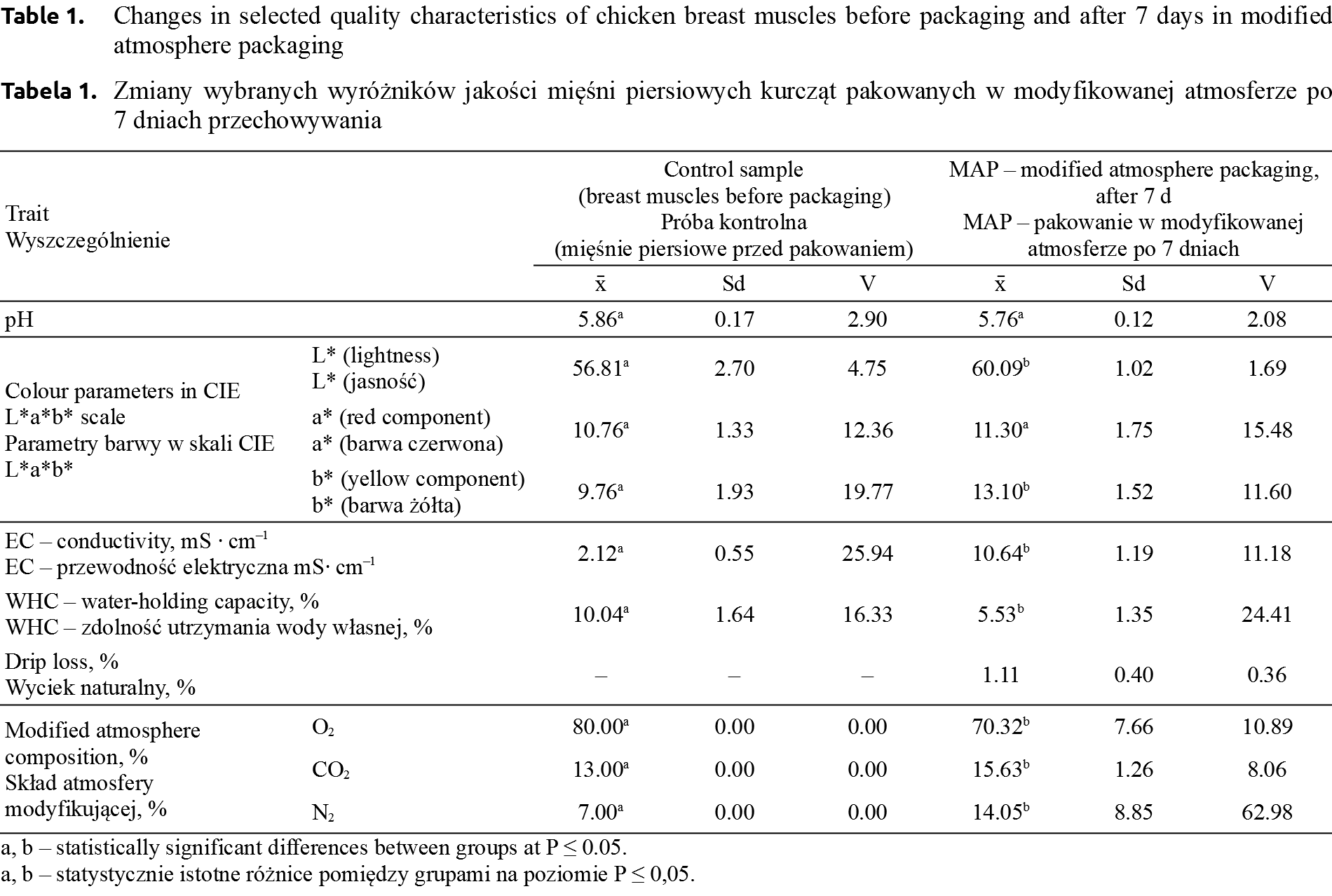

Table 1 presents a comparison of the quality of meat stored in a modified atmosphere after seven days of storage with the control group. In the case of this storage method, most of the quality characteristics underwent significant changes. A slight (0.1) decrease in meat pH was noted. Changes in the colour of the muscles were observed as well. All meat colour parameters (lightness (L*), red component (a*) and yellow component (b*)) had increased after a week of meat storage. In the case of lightness (L*) and yellow colour (b*), the differences were confirmed statistically (P ≤ 0.05). Electrical conductivity in the meat samples was more than 8 ms/cm higher after seven days of storage (P ≤ 0.05). The water-holding capacity (WHC) was nearly twice as high in the control sample of meat prior to packaging (P ≤ 0.05). After seven days of storage in a modified atmosphere, the drip loss exceeded 1%. The composition of the modified atmosphere was also changed after the storage period. The percentage of oxygen decreased by nearly 10%, the share of carbon dioxide increased by more than 2.5%, and the share of nitrogen increased more than two-fold. All differences in the composition of the atmosphere between the groups were confirmed statistically (P ≤ 0.05).

Table 2 compares the quality of meat stored in a vacuum after seven days with the quality of the control meat. The pH of the meat did not change during the storage period. After seven days, the red colour (a*) of the meat increased, while the intensity of yellow colour (b*) decreased. The differences were statistically confirmed at P ≤ 0.05. After the storage period, the electrical conductivity of the meat increased almost six-fold (P ≤ 0.05). A 3.64% reduction in water-holding capacity was also demonstrated after one week of storage in vacuum conditions, and the drip loss reached 2.68%.

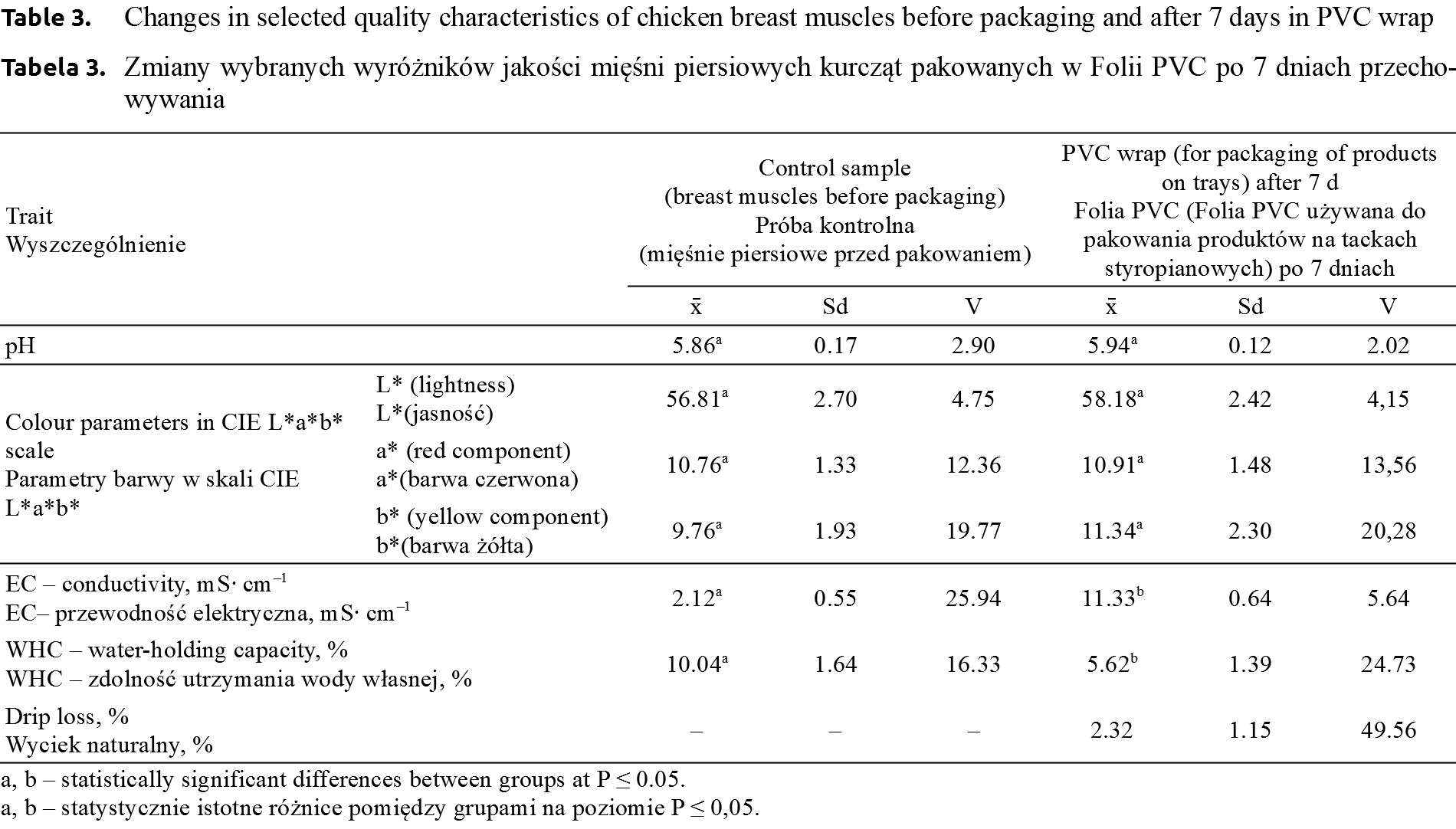

The data in Table 3 show slight differences in the pH and colour parameters (L*, a*, b*) of meat stored for seven days in PVC wrap on a foamed polystyrene tray. These features increased after the storage period relative to the control, but no statistical differences were found between the groups. Electrical conductivity increased significantly by over 9 ms/cm (P ≤ 0.05). The water-holding capacity of the breast muscles was also shown to decrease by nearly half after seven days of storage in PVC wrap (P ≤ 0.05), and the drip loss was 2.32%.

Table 4 presents the data on the characteristics of chicken breast muscles after seven days of storage in different packaging systems. The data show significant differences in some qualitative characteristics. The pH of the muscles ranged from 5.76 to 5.94 and was highest in the muscles packed in PVC wrap. The differences were confirmed statistically (P ≤ 0.05). In the case of meat colour, the highest variation was found for yellow colour (b*), whose value differed significantly between all packaging methods (P ≤ 0.05). The value of the yellow component (b*) of the vacuum-packed meat was 7.61, which was about 5.5 less than in the case of muscles packaged in a modified atmosphere (P ≤ 0.05). The muscles packed in a modified atmosphere also had significantly lower conductivity, by 0.69–1.25, than muscles packaged by other methods (P ≤ 0.05). The water-holding capacity of the breast muscles packed in MAP and PVC was similar, and was about 0.8 pp lower than the WHC of vacuum-packed muscles. However, in this case no statistical differences were found between the groups. In the case of muscles packed in MAP, drip loss was significantly lower (by more than 1.2%) than in muscles packed by other methods (P ≤ 0.05).

The quality of poultry meat product depends to a certain extent on the technological processes it goes through. To maintain the highest possible quality, the right packaging must be used. Modern packaging should perform several basic roles in terms of its contents protection, branding, consumer information, profitability, logistics and recycling [Leszczyński and Żbikowska 2016Leszczyński, K., Żbikowska, A. (2016). Food packages and packing [Selected issues Opakowania i pakowanie żywności. Wybrane zagadnienia]. Wydaw. SGGW. Warszawa [in Polish].]. Well-chosen packaging must protect the product against the harmful effects of the environment (microorganisms, light, oxygen, or dust) and against mechanical and physical factors (deformation or drying out) [Zmarlicki 2000Zmarlicki, S. (2000). The process in food packaging in a modified atomosphere and active packaging [Proces w zakresie pakowania żywności w modyfikowanej atmosferze oraz pakowania aktywnego]. Przemysł Spożywczy, 11, 31–35 [in Polish].]. The logistical function of packaging is important for the consumer, producer and distributor, and is often a decisive factor in the consumer choice. The package should be easy to heat-seal, handle, store and open.

Of a variety of meat packaging systems, modified atmosphere packaging is the most popular one. The purpose of this system is to create conditions inside the package that will prolong the shelf life of the product. Microbiological, enzymatic and biochemical processes in the meat are slowed down. Efforts are also made to maintain high meat quality and improve the aesthetics of the packaged product [Jakobsen and Berstelsen 2000Jakobsen, M., Berstelsen, G. (2000). Colour stability and lipid oxidation of fresh beef. Development of a response surface model for predicting the effects of temperature, storage time and modified atmosphere composition. Meat Sci., 1 (54), 49–57. https://doi.org/10.1016/s0309-1740(99)00069-8.]. In comparison to traditional packaging, the shelf life of meat packed in the MAP system can be doubled or even quadrupled [Makała 2015Makała, H. (2015). Packages for the meat industry [Opakowania dla przemysłu mięsnego]. Gospodarka Mięsna, 4, 28–32 [in Polish].]. The system consists in replacing air (when the packaging is closed) with a properly composed mixture of the gases: carbon dioxide (CO2), oxygen (O2) and nitrogen (N2), with the composition depending on the type of meat. According to Orkusz [2015Orkusz, A. (2015). Packing of poultry meat in a modified atmosphere [Pakowanie mięsa drobiowego w modyfikowanej atmosferze]. Nauki Inżynierskie i Technologie, 2(17), 41–50 [in Polish].], the composition of the MAP gas mixture for the chicken muscle, extending the storage period and preserving the appropriate colour, is 75% CO2, 20% N2 and 5% O2. The composition of gases is not constant throughout the storage period. This is due to the penetration of gases through the packaging material and biochemical processes taking place in the product during storage [Hać-Szymańczuk 2013Hać-Szymańczuk, E. (2013). Microbiological aspects of packaging in a modified atmosphere [Aspekty mikrobiologiczne pakowania w zmodyfikowanej atmosferze]. Gospodarka Mięsna, 5, 22–24 [in Polish].], which has been confirmed in our research.

Each of the gases has a specific function in preserving the properties of the packaged products. They can positively or negatively affect the product. Carbon dioxide (CO2) is known for its strong properties inhibiting the growth of bacteria (particularly Gram-negative) [Lipińska et al. 2015Lipińska, A., Łopacka, J., Sakowska, A., Rafalska, U., Żontała, K. (2015). The effect of packaging in a modified atmosphere on the quality of meat and meat products [Wpływ pakowania w modyfikowanej atmosferze na jakość mięsa i produktów mięsnych]. Opakowanie, 9, 76–78 [in Polish].]. The inhibiting effect of CO2 is most effective at a concentration of about 20–40% [Smith et al. 1990Smith, J.P., Ramaswany, H.S., Simpson, B.K. (1990). Developments in food packaging technology. Part II. Storage aspects. Trends Food Sci. Technol., 1(5), 111–118. https://doi.org/10.1016/0924-2244(90)90086-e.]. In the case of meat, an excessive concentration of CO2 causes a sour taste to appear on its surface. Furthermore, over time the film collapses and sticks to the product due to the absorption of CO2 by the raw meat, which reduces the pressure in the mixture. CO2 is widely used primarily for products with high water content, because it reduces pH as a result of its dissolution and the formation of carbonic acid [Burczyk et al. 2015Burczyk, E., Chwastowska-Siwiecka, I., Kondratowicz, J. (2015). Selected methods for packaging meat and meat products [Wybrane metody pakowania mięsa i produktów mięsnych]. Gospodarka Mięsna, 4, 18–24 [in Polish].]. Nitrogen is a neutral gas. Its main function is to fill up the volume of the package to 100%. This prevents the ‘collapse’ of the package caused by the dissolution of carbon dioxide [Borowy and Kubiak 2008bBorowy, T., Kubiak, M. (2008b). Packaging systems for meat and meat products – packing in an atmosphere of protective gases [Systemy pakowania mięsa i przetworów mięsnych – pakowanie w atmosferze gazów ochronnych]. Gospodarka Mięsna, 9, 26–28 [in Polish].]. The main role of oxygen is to maintain the red colour of meat (oxymyoglobin) by delaying the formation of metmyoglobin. Oxygen also restricts the growth of anaerobic microbes; however, at the same time promotes the growth of aerobic (spoilage) bacteria [Kubiak 2003Kubiak, A. (2003). Gases in the food industry [Gazy w przemyśle spożywczym]. Przemysł Spożywczy, 8, 58–61 [in Polish].].

Vacuum packaging is one form of modified atmosphere packaging. It consists in placing the product in a special plastic bag, removing about 98–99% of the air, and then sealing it, usually by heat sealing [Rudy et al. 2007Rudy, M., Zin, J., Głodek, E. (2007). The effect of the composition of a modified atmosphere on the shelf-life of meat and cold cuts during refrigeration [Wpływ składu modyfikowanej atmosfery na trwałość mięsa i wędlin podczas chłodniczego przechowywania]. Annales Universitatis Mariae Curie-Skłodowska Lublin-Polonia, 1, 78–84 [in Polish].]. The purpose of vacuum packaging is to extend the shelf life of the product and to maintain the best possible sensory characteristics desired by consumers. This type of system provides excellent protection for packaged meat, preventing in particular the growth of microorganisms, loss of muscle mass, oxidation of the meat surface, drying out (including changes in colour), and mixing and loss of aromas during storage [Gajewska-Szczerbal 2005Gajewska-Szczerbal, H. (2005). [Packaging of meat and meat products, I [Pakowanie mięsa i przetworów mięsnych, I]. Gospodarka Mięsna, 7, 6–9 [in Polish].]. Meat is an unstable raw material and is susceptible to various chemical, physical and microbiological changes. According to Pisula and Pośpiech [2011Pisula, A., Pośpiech, E. (2011). Meat – fundamentals of science and technology [Mięso - podstawy nauki i technologii]. Wydaw. SGGW, Warszawa [in Polish].], the quality of vacuum-packed meat is influenced by factors associated with the quality parameters of the product itself, such as water activity, redox potential, hydrogen ion concentration, type and content of preservatives, or the amount and type of microflora present. External factors influencing product quality include the composition of the atmosphere around the product, packaging conditions, temperature, and exposure to light. According to Czapski and Michniewicz [1997Czapski, J., Michniewicz, J. (1997). The effect of packaging on food quality during storage [Wpływ opakowania na zmiany jakości żywności podczas przechowywania]. Przemysł Spożywczy, 10, 15–19 [in Polish].], the removal of oxygen from the package limits the growth of unfavourable microflora, particularly aerobic bacteria responsible for food spoilage, rancidity and changes in meat colour. If the oxygen content in the package is too low, psychrophilic anaerobes such as Clostridium botulinum may proliferate. To prevent this, the oxygen content in the packaging should be at least 2%. According to Gajewska-Szczerbal [2005Gajewska-Szczerbal, H. (2005). [Packaging of meat and meat products, I [Pakowanie mięsa i przetworów mięsnych, I]. Gospodarka Mięsna, 7, 6–9 [in Polish].], vacuum-packed meat should be stored at 0–2°C because the dominant microbes are lactic acid bacteria, which produce carbon dioxide and are antagonistic to spoilage bacteria. Another quality characteristic of meat that consumers consider is its colour. The composition of the atmosphere around the product generates the pigment deoxymyoglobin. It has a purple-red or purple colour, which may be unacceptable to the consumer. Another common occurrence in the vacuum packaging system is the slow accumulation of meat juice in the plastic film. New vacuum packaging methods are used to prevent this. Pi-Vac vacuum packing involves packing ‘hot’ meat immediately after slaughter in a special film with low permeability for oxygen and water vapour before the onset of rigor mortis. The advantages of Pi-Vac include improved tenderness, preservation of meat colour and aromas during storage, minimization of loss of meat juice, and extension of the shelf life of meat due to the small initial number of microbes [Makała 2011Makała, H. (2011). Trends in packaging of meat and meat products [Trendy w opakowaniach mięsa i przetworów mięsnych]. Postępy Nauki i Technologii Przemysłu Rolno-Spożywczego, 66, 1 [in Polish].]. The skin packaging technique involves placing the product on a tray and surrounding it with a closely adhering film. In this method the meat can still age, which improves its tenderness and flavour [Makała 2011Makała, H. (2011). Trends in packaging of meat and meat products [Trendy w opakowaniach mięsa i przetworów mięsnych]. Postępy Nauki i Technologii Przemysłu Rolno-Spożywczego, 66, 1 [in Polish].].

According to Kondratowicz [2005Kondratowicz, J. (2005). The sensory quality and total micro-organism count in breast muscles of broiler chickens depending on the method and period of cold storage [Jakość sensoryczna oraz ogólna liczba drobnoustrojów w mięśniach piersiowych kurcząt brojlerów w zależności od metody i czasu przechowywania chłodniczego]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 3(44), Supl., 78–87 [in Polish].] and Kondratowicz et al. [2011Kondratowicz, J., Chwastowska-Siwiecka, I., Burczyk, E., Piekarska, J., Kułdo, Ż. (2011). Sensory and microbiological assessment of turkey hens breast muscles depending on method and time of cold storage [Ocena sensoryczna i mikrobiologiczna mięśni piersiowych indyczek w zależności od metody i czasu przechowywania chłodniczego]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 3(76), 143–152 [in Polish].], both the method and the duration of refrigeration at 2°C affect the sensory quality of the breast muscles of broilers, with a faster rate of change in muscles stored in atmospheric air than in an atmosphere of controlled gases. When vacuum-packed meat is stored too long, its tenderness deteriorates and a characteristic vacuum smell arises due to the growth of certain microorganisms [Brooks 2007Brooks, C. (2007). Beef Packaging. National Cattlemen’s Beef Association Centennial, 1-3.]. As consumers expect a safe and high-quality product from the producer, well-selected packaging should ensure that raw poultry has an appropriate shelf life. Vacuum-packed products have an extended shelf life. Particular attention is paid to the barrier properties of packaging. For this purpose, heat-shrink packaging moulded on thermoformers and heat-sealed vacuum bags are used [Danyluk et al. 2004Danyluk, B., Gajewska–Sczerbal, H., Pyrcz, J., Kowalski, J. (2004). Microbiological shelf-life of vacuum-packed cold cuts [Trwałość mikrobiologiczna wędlin pakowanych próżniowo]. Acta Scien. Pol., Technol. Aliment., 3(2), 37–44 [in Polish].]. The colour in the vacuum system is less appealing than in the case of other packaging methods [Borowy and Kubiak 2008aBorowy, T., Kubiak, M. (2008a). Packaging systems for meat and meat products – vacuum packing [Systemy pakowania mięsa i przetworów mięsnych - pakowanie próżniowe]. Gospodarka Mięsna, 8, 56–60 [in Polish].]. In MAP packaging, the effect on the properties of the meat depends on the oxygen concentration. If the oxygen concentration in the packaging is low, the shelf life is extended, but the colour deteriorates. According to studies by Krala [Krala 1999Krala, L. (1999). The impact of controlled and modyfied atmosphere on the properties of cooled chicken meat [Oddziaływanie atmosfery kontrolowanej i modyfikowanej na właściwości chłodzonego mięsa kurcząt]. Zesz. Nauk. Rozprawy Naukowe, Politechnika Łódzka, 255, 5–141 [in Polish].], the storage of leg and breast muscles at 2 ± 1°C in MAP may increase the shelf-life of refrigerated chickens as much as 2 or 3 times in relation to the regular refrigeration in atmospheric air. According to Rudy et al. [2007Rudy, M., Zin, J., Głodek, E. (2007). The effect of the composition of a modified atmosphere on the shelf-life of meat and cold cuts during refrigeration [Wpływ składu modyfikowanej atmosfery na trwałość mięsa i wędlin podczas chłodniczego przechowywania]. Annales Universitatis Mariae Curie-Skłodowska Lublin-Polonia, 1, 78–84 [in Polish].], this system provides many benefits to the producer. The colour of meat is a key factor determining its purchase [Lynch et al. 1986Lynch, N.M., Kastner, C.L., Kropf, D.H. (1986). Consumer acceptance of vacuum packaged ground beef as influenced by product color and educational materials. J. Food Sci., 51(2), 253–255. https://doi.org/10.1111/j.1365-2621.1986.tb11102.x.]. Even a slight deviation from the normal colour disqualifies the product, which is often returned to the manufacturer. The use of a modified atmosphere reduces losses. The colour of the product is determined by the amount of myoglobin and its further transformations. The level of haem pigments depends on sex, age, species, diet, physical activity, degree of exsanguination, and muscle type [Grabowski and Kijowski 2018Grabowski, T., Kijowski, J. (2018). Poultry meat and meat products. Technology, hygiene and quality [Mięso i przetwory drobiowe. Technologia, higiena, jakość]. Wydaw. WNT, Warszawa [in Polish].]. Fresh poultry meat should have a light red colour. A darker colour indicates an increase in oxidized myoglobin and may cause the consumer to reject it as not fresh. According to Grabowski and Kijowski [2018Grabowski, T., Kijowski, J. (2018). Poultry meat and meat products. Technology, hygiene and quality [Mięso i przetwory drobiowe. Technologia, higiena, jakość]. Wydaw. WNT, Warszawa [in Polish].], the structure of the breast muscles is dominated by white fibres with low content of myoglobin. The colour of meat, apart from being an important feature for consumers purchasing the product, is also an indicator of its suitability for processing [Werner and Wicke 2008Werner, C., Wicke, M. (2008). Farbvariabilität und -stabilität von Hähnchenbrust in Schutzgasverpackung. Fleischwirtschaft, 88(9), 130–132., Żywica et al. 2011Żywica, R., Charzyńska, D.G., Banach, J.K. (2011). The effect of electric stunning of chickens with a device of our own construction on meat colour [Wpływ procesu oszałamiania elektrycznego kurcząt za pomocą urządzenia własnej konstrukcji na barwę mięsa]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 1 (74), 52–67 [in Polish].]. The colour of meat can be influenced by a number of factors, such as genotype [Pietrzak et al. 2013Pietrzak, D., Michalczuk, M., Niemiec, J., Mroczek, J., Adamczak, L., Łukasiewicz, M. (2013). Comparison of selected quality indicators of the meat of fast and slow growing chickens [Porównanie wybranych wyróżników jakości mięsa kurcząt szybko i wolno rosnących]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 2(87), 30–38 [in Polish].], age, or post-mortem treatment, e.g. the exsanguination rate [Fletcher 2002Fletcher, D.L. (2002). Poultry meat quality. World’s Poultry Sci. J., 58(6), 131–145. https://doi.org/10.1079/wps20020013.]. There are studies showing that the system in which poultry is raised affects the intensity of meat colour [Skomorucha and Sosnówka-Czajka 2015Skomorucha, I., Sosnówka-Czajka, E. (2015). The effect of the system of housing broiler chickens on selected meat quality parameters [Wpływ systemu utrzymania kurcząt brojlerów na kształtowanie się wybranych parametrów jakościowych mięsa]. Rocz. Nauk. Zoot., 42, 1, 45–53 [in Polish].]. Chen et al. [2013Chen, X., Jiang, W., Tan, H.Z., Xu, G.F., Zhang, X.B., Wei, S., Wang, Q. (2013). Effects of outdoor access on growth performance, carcass composition, and meat characteristics of broiler chickens. Poultry Sci., 92, 435–443. https://doi.org/10.3382/ps.2012-02360.] and Sales [2014Sales, J. (2014). Effects of access to pasture on performance carcass composition and meat quality in broilers. A meta-analysis. Poultry Sci., 93, 1523–1533. https://doi.org/10.3382/ps.2013-03499.] have reported that the meat of poultry raised with access to a run had a more intense yellow colour. This is probably linked to access to plants rich in carotenoids. However, in research by Tong et al. [2014Tong, H.B., Wang, Q., Lu, J., Zou, J.M., Chang, L.L., Fu, S.Y. (2014). Effect of free-range days on a local chicken breed: Growth performance, carcass yield, meat quality, and lymphoid organ index. Poultry Sci., 93, 1883–1889. https://doi.org/10.3382/ps.2013-03470.] and by Skomorucha and Sosnówka-Czajka [2015Skomorucha, I., Sosnówka-Czajka, E. (2015). The effect of the system of housing broiler chickens on selected meat quality parameters [Wpływ systemu utrzymania kurcząt brojlerów na kształtowanie się wybranych parametrów jakościowych mięsa]. Rocz. Nauk. Zoot., 42, 1, 45–53 [in Polish].], the breast muscles of chickens with access to a run had higher saturation with red (a*) and less yellow (b*) than chickens without access to a run. Pietrzak et al. [2013Pietrzak, D., Michalczuk, M., Niemiec, J., Mroczek, J., Adamczak, L., Łukasiewicz, M. (2013). Comparison of selected quality indicators of the meat of fast and slow growing chickens [Porównanie wybranych wyróżników jakości mięsa kurcząt szybko i wolno rosnących]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 2(87), 30–38 [in Polish].] have reported that the breast muscles of slow-growing chickens were lighter in colour than those of fast-growing chickens. In our research comparing different packaging methods, after seven days of storage the vacuum-packed muscles had a lighter colour (L*). This is evidenced by the lower values of the L* component and higher values of the a* component. Studies by many authors indicate high variation in colour parameters, with lightness (L*) of chicken muscle ranging from 41 to 67 [Berri et al. 2005Berri, C., Le Bihan-Duval, E., Baèza, E., Chartrin, P., Picgirard, L., Jehl, N., Quentin, M., Picard, M., Duclos, J. (2005). Further processing characteristics of breast and leg meat from fast-, medium- and slow growing commercial chickens. Anim. Res., (2), 123–134. https://doi.org/10.1051/animres:2005008., Werner and Wicke 2008Werner, C., Wicke, M. (2008). Farbvariabilität und -stabilität von Hähnchenbrust in Schutzgasverpackung. Fleischwirtschaft, 88(9), 130–132.], which is confirmed by the present study. According to Chwastowska-Siwiecka et al [2012Chwastowska-Siwiecka, I., Baryczka, I., Skiepko, N. (2012). Effect of the packaging metod and period cold storage on the physicochemical and sensory properties of rabbit meat [Wpływ metody pakowania i czasu chłodniczego przechowywania na właściwości fizykochemiczne i sensoryczne mięsa króliczego]. Chłodnictwo: organ Naczelnej Organizacji Technicznej, 47, 7–8, 56–60 [in Polish].], rabbit meat packed in a protective gas atmosphere and stored for 20 days had higher acidity (pHu) and a lighter colour than vacuum-packed thigh muscles.

Another important element is tenderness, which is expressed by parameters such as the hardness, springiness, chewiness or gumminess of the muscle. The age of birds plays a significant role in determining meat tenderness. The meat of a young broiler chicken is more tender than the meat of older birds, due to the thin muscle fibres and less mature collagen. Other factors affecting the tenderness of meat include loading, transport, slaughter procedures and further technological processes [Zdanowska-Sąsiadek et al. 2013Zdanowska-Sąsiadek, Ż., Michalczuk, M., Marcinkowska-Leszak, M., Damaziak, K. (2013). Factors influencing the sensory characteristics of poultry meat [Czynniki kształtujące cechy sensoryczne mięsa drobiowego]. Bromatologia i chemia toksykologiczna, XLVI, 3, 344–353 [in Polish].]. Meat with better water-holding capacity is more tender after cooking than meat with poorer water-holding capacity. Immediately after slaughter, poultry meat has a high water-holding capacity, which decreases with time as the pH decreases. After the ageing period, the pH and water-holding capacity of meat increase [Bechtel 1986Bechtel, P. (1986). Muscle as Food. Academic Press Inc., Orlando.].

The data obtained in the study indicate differences in the quality of meat during storage in various packaging systems. There were slight changes in pH, which ranged from 5.76 to 5.94, but this was not indicative of the PSE or DFD defect. In a study by Jakubowska et al. [2004Jakubowska, M., Gardzielewska, J., Kortz, J., Karamucki, T., Buryta, B., Rybarczyk, A., Otolińska, A., Natalczyk-Szymkowska, W. (2004). Rormation of physicochemical properties of broiler chicken Brest muscles depending on pH value measured 15 minutes after slaughter [Kształtowanie się wybranych cech fizykochemicznych mięśni piersiowych w zależności od wartości pH mierzonego 15 minut po uboju u kurcząt brojlerów]. Acta Sci. Pol., Technol. Aliment. 3(1), 139–144 [in Polish].], the pH values of normal meat were pH1 6.07 and pH24 5.72. The pH of meat is a quality indicator that depends on glycogen stores in the muscles [Tong et al. 2014Tong, H.B., Wang, Q., Lu, J., Zou, J.M., Chang, L.L., Fu, S.Y. (2014). Effect of free-range days on a local chicken breed: Growth performance, carcass yield, meat quality, and lymphoid organ index. Poultry Sci., 93, 1883–1889. https://doi.org/10.3382/ps.2013-03470.]. Some authors point out a relationship between the rearing system and the pH of chicken muscles [Fanatico et al. 2007Fanatico, A.C., Pillai, P.B., Emmert, J.L., Owens, C.M. (2007). Meat quality of slow and fast growing chicken genotypes fed low nutrients or standard diets and raised indoors or with outdoor access. Poultry Sci., 86, 2245–2255. https://doi.org/10.1093/ps/86.10.2245., Brown et al. 2008Brown, S.N., Nute, G.R., Baker, A., Hughes, S.I., Warriss, P.D. (2008). Aspects of meat and eating quality of broiler chickens reared under standard, maize-fed, free-range or organic systems. Brit. Poultry Sci., 49, 2, 118–124. https://doi.org/10.1080/00071660801938833., Chen et al. 2013Chen, X., Jiang, W., Tan, H.Z., Xu, G.F., Zhang, X.B., Wei, S., Wang, Q. (2013). Effects of outdoor access on growth performance, carcass composition, and meat characteristics of broiler chickens. Poultry Sci., 92, 435–443. https://doi.org/10.3382/ps.2012-02360.]. According to Pietrzak et al. [2013Pietrzak, D., Michalczuk, M., Niemiec, J., Mroczek, J., Adamczak, L., Łukasiewicz, M. (2013). Comparison of selected quality indicators of the meat of fast and slow growing chickens [Porównanie wybranych wyróżników jakości mięsa kurcząt szybko i wolno rosnących]. ŻYWNOŚĆ. Nauka. Technologia. Jakość, 2(87), 30–38 [in Polish].], the pH of the meat depends on both the rearing system and the genotype. Many authors report that the pH24 of chicken breast muscle ranges from 5.6 to 6.1, which has been confirmed by our research [Berri et al. 2005Berri, C., Le Bihan-Duval, E., Baèza, E., Chartrin, P., Picgirard, L., Jehl, N., Quentin, M., Picard, M., Duclos, J. (2005). Further processing characteristics of breast and leg meat from fast-, medium- and slow growing commercial chickens. Anim. Res., (2), 123–134. https://doi.org/10.1051/animres:2005008., Gornowicz 2008Gornowicz, E, Pietrzak, M. (2008). The effect of the origin of broiler chickens on the carcass characteristics and quality of breast muscles [Wpływ pochodzenia kurcząt brojlerów na cechy rzeźne i jakość mięśni piersiowych]. Rocz. Inst. Przem. Mięs. Tłuszcz., 46(1), 94–104 [in Polish]., Rycielska et al. 2010Rycielska, J., Jarosiewicz, K., Słowiński, M. (2010). The effect of selected antemortem factors on the quality of chicken meat [Wpływ wybranych czynników przyżyciowych na jakość mięsa kurcząt]. Med. Wet., 66(11), 770–773 [in Polish].]. The active acidity of meat also has a great impact on its colour. In an environment of pH 5.9–6.2, the muscle takes on a favourable colour. In a less acidic environment (pH 6.3–6.4), the meat contains less oxymyoglobin and the colour is similar to that of meat with the DFD defect (dark, firm and dry).

An important indicator of the integrity of cell membranes in muscle tissue is electrical conductivity (EC) [Honikel and Garrido 1993Honikel, K.O., Garrido, M.D. (1993). Beziehungen zwischen frueh-postmortem Merkmalen bei Schweinefleisch. Mitteilungsblatt der Bundesanstalt fur Fleischforschung Kulmbach, 32, 170–176.]. EC increases with the weakening of structural membranes. This is linked to the increase in the water content inside the muscle, and thus to the movement of fluids in the intra- and intercellular spaces [Domaradzki 2014Domaradzki, P. (2014). Changes in the physicochemical properties of the skeletal muscles of four categories of beef cattle during 12-day vacuum ageing [Zmiany właściwości fizykochemicznych mięśni szkieletowych czterech kategorii bydła rzeźnego w okresie 12-dniowego dojrzewania próżniowego]. Roczniki Naukowe Polskiego Towarzystwa Zootechnicznego, 10, 4, 125–140 [in Polish].]. In our study, in each case a significant increase in the electrical conductivity of the breast muscles was observed, irrespective of the packaging method.

The variety of packaging systems makes it possible to reduce muscle losses. According to Sakowska et al. [2014Sakowska, A., Konarska, M., Guzek, D., Głąbska, D., Wierzbicka, A. (2014). Characterization of selected meat packing systems in relations to consumer preferences and economic aspects [Charakterystyka wybranych systemów pakowania mięsa w odniesieniu do preferencji konsumentów i aspektów ekonomicznych]. Zeszyty Naukowe SGGW Warszawa, 14(29), 2, 203–213 [in Polish].], the greatest losses in meat mass occur in traditional packaging. Hence, the use of vacuum packaging and modified atmosphere packaging reduce losses of packaged meat during storage.

The growing demands of customers and the continued growth of the meat market have led producers to search for and apply new packaging solutions. Current meat packaging systems are able to meet consumer demands. They improve colour stability, extend shelf life and reduce losses of meat juice during storage. However, meat packed using various systems undergoes some changes during storage. The research confirmed significant differences in the quality characteristics of meat packed by different methods after seven days of storage. Vacuum-packed chicken breast muscles had a lighter colour and the highest electrical conductivity. These muscles also showed a higher drip loss, which may be of importance in processing.

This work was financially supported by the Siedlce University of Natural Sciences and Humanities, project no. UPH/WP/IBiHZ/temat/370/14/S.

Received: 10 Apr 2019

Accepted: 5 Jul 2019

Published online: 18 Sep 2019

Accesses: 1418

Kot vel Ławecka, K., Banaszewska, D., Biesiada-Drzazga, B., (2019). The effect of packaging systems on selected quality characteristics of poultry meat. Acta Sci. Pol. Zootechnica, 18(2), 3–12. DOI: 10.21005/asp.2019.18.2.01.